Spark & Spark Multi View

Visual inspection, automated by AI

Transform your quality control with your Spark inspection kit.

Kits Spark

Your automated industrial inspection.

No matter how complex your parts are, Spark kits offer a robust, turnkey solution to automate your quality control.

Turnkey inspection kits.

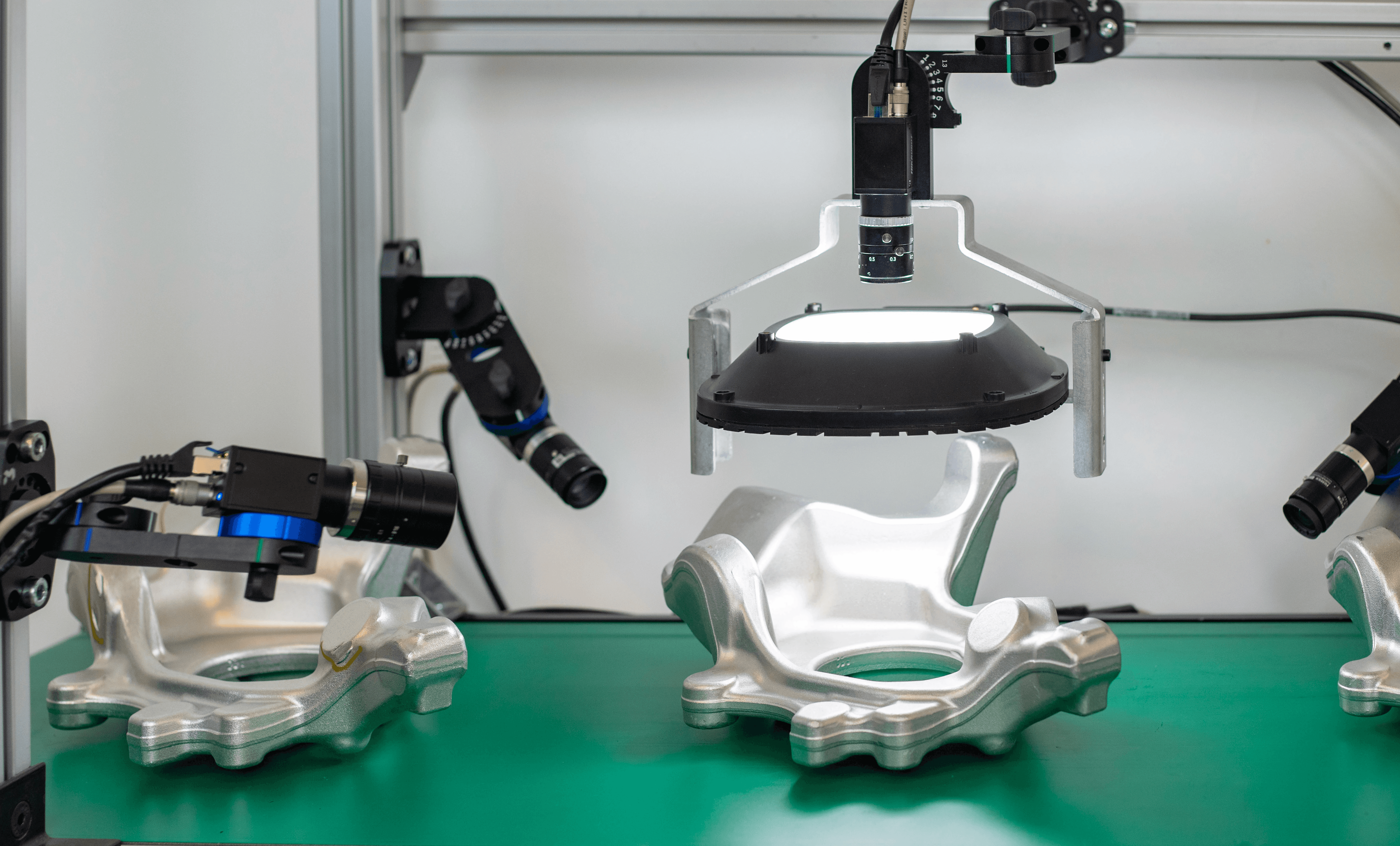

Your kit comes with HD cameras, lighting, poly-articulated arms, a touch screen, and a computing, control, and connectivity unit.

Quick Start

Spark is quick to start because it relies only on a few dozen good parts, eliminating the need for a large library of vision tools or collecting 50 examples of each defect.

Connect to your line

You can easily connect the Spark automaton to your production line's one to eject non-conforming pieces.

Spark Software

Your AI-powered inspection software.

Our software offers you precise analyses and fast anomaly detection thanks to its embedded AI based on deep learning. It automatically provides severity adjustment to tolerate acceptable variabilities between healthy parts and to report anomalies making the product defective.

Advanced Algorithms

Spark uses internally developed artificial intelligence algorithms for state-of-the-art anomaly detection, recognized as among the best in the industry.

Learning Variability

The system learns and accepts the natural variations between conforming parts, thus avoiding false rejections.

Automated Analysis

The captured images (up to 4 per part) are automatically analyzed by the algorithms, allowing the system to provide an overall quality decision for the part. The setting of sorting target performance is done at once for all cameras, and a single decision is sent to the PLC for part rejection. The automation management is greatly simplified.

Spark & Spark Multi View

One technology,

two solutions.

Spark offers a unique camera inspection solution ideal for simple geometries, while Spark Multi View enables full coverage of the volume of complex parts with multiple cameras.

Spark

For simple and precise inspections with a camera.

This product is perfect for production lines where space is limited and where a camera can cover the entire inspection process to be performed. Spark is easy to integrate into existing production environments, offering a quick and reliable inspection solution for visual quality control.

Spark Multi View

New

For complex inspections thanks to multi-camera analysis.

New to our product line, Spark Multi View amplifies inspection capabilities with multiple cameras, providing a comprehensive view for more complex analyses. This system is ideal for applications where it is necessary to inspect multiple faces of parts with a simple and quick to set up vision integration expertise.

Comparison

Make an informed decision for your quality control.

Our detailed comparison chart presents the key differences between Spark, competing solutions, and manual inspection.

Customer Success

Achieve your quality goals with our expert support team.

Our team supports you in improving your quality control processes.

Supports you in the implementation of the kit and the necessary adjustments.

And proactively monitors performance to ensure continuous improvement.

Continuous Improvement

Innovation and continuous development

Stay on the cutting edge with our regular and free updates. Our artificial intelligence team is constantly refining algorithms to enhance anomaly detection under all conditions.

Simultaneously, we gather your feedback to refine the user experience and integrate the most relevant features into your production context.

Customer Support

Remote Assistance and Support

Benefit from fast support in any circumstances. Our ability to remotely access your systems allows us to quickly identify and resolve issues, minimizing interruptions to your production. Our team is ready to provide the assistance needed to maintain your vision system at its best.

Applications

Innovation and precision for all industrial applications

Spark is ideal for a variety of industries such as cosmetics, packaging, automotive, and many others. It is capable of inspecting various materials such as metal, glass, plastic, or matte or glossy surface states, thus meeting a wide range of inspection needs.

How can our anomaly detection solution improve the quality of our products?

What are the main key performance indicators (KPIs) that our solution can help you track?

How can our solution be integrated into our existing quality management system?

What are the security and privacy guarantees offered by our solution?

What are the levels of technical support and maintenance included in the use of our solution?